◄ Previous Page

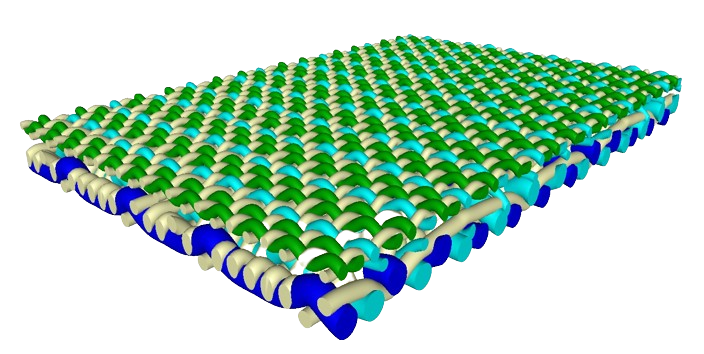

Shute Support Binder (SSB)

It has two separate single layer fabrics bound together by separated yarns called binders oriented in MD or CD

Product Fatures:

- ✤ SSB Triple Layer Fabrics are most advanced fabric design and offers many benefits to papermaker over other designs. These fabrics have two separate single layer fabrics bound together by separated yarns called binders. The binder yarns can be oriented both CD (Weft SSB) and MD (Warp SSB). The fine top side of the fabric improves formation & fines retention. It also reduces wire mark, which is a major consideration in fine papers. The coarse bottom layer is specifically engineered to ensure long fabric life. The large filling and warp yarns allow decreased running loads. Shalimar has both Weft SSB and Warp SSB with different combinations in its product portfolio

- ✤ Supremo AT for fine paper grades;

- ✤ Sigma XT for packaging grades

Factory : No. 77, Netaji Subhas Road, Uttarpara, Hooghly 712258

Factory : No. 77, Netaji Subhas Road, Uttarpara, Hooghly 712258